FEATURES

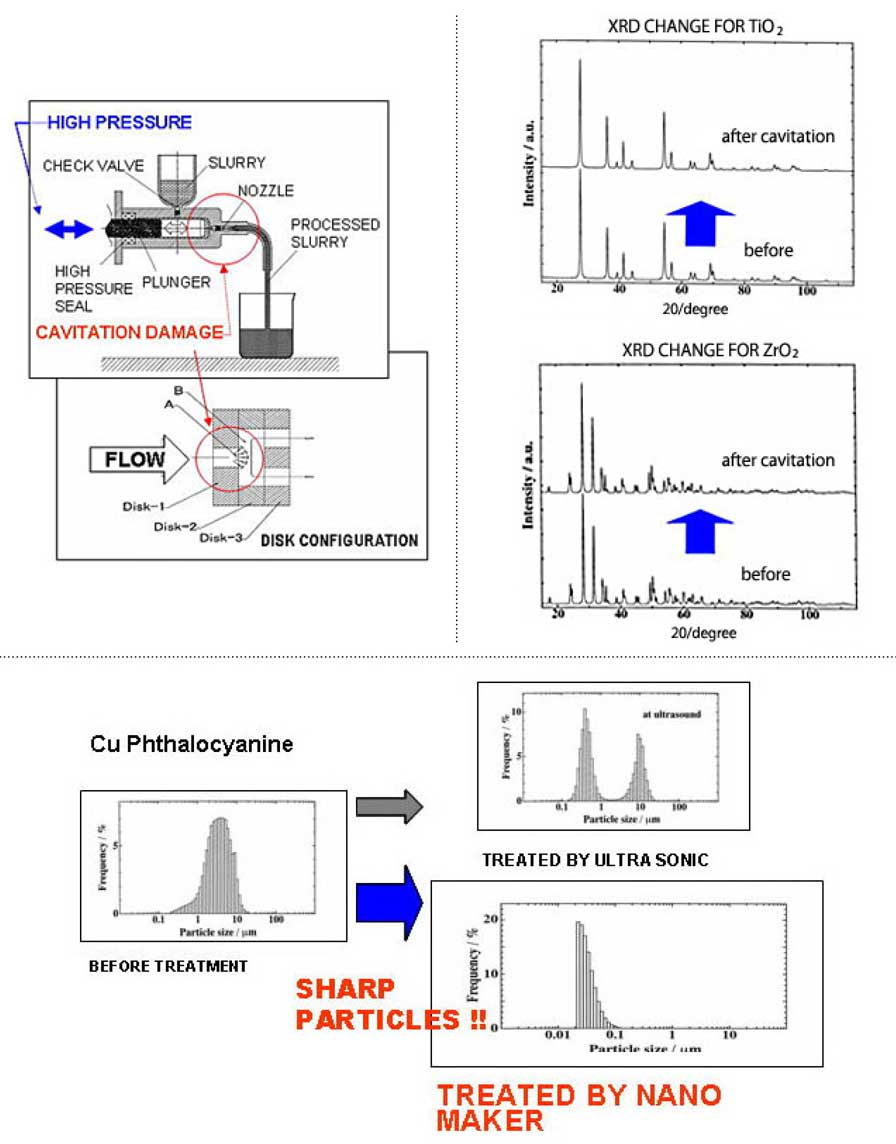

Ultra High Pressurized slurry flow design,with the best formation of diamond disks, & efficient nozzle arrangement is able to :

ensure the perfect development and collapse of cavities, discharging such high energies (Cavitation Damage)

improve the basic functions, crushing, dispersing, emulsifyiung, by such a high efficient cavition damage

provide longer parts life

Long established experience in designing, manufacturing, and engineeing ensures :

better man / machineinterface

easy cleaning, maintenance of the systems

SYSTEM CONCEPT

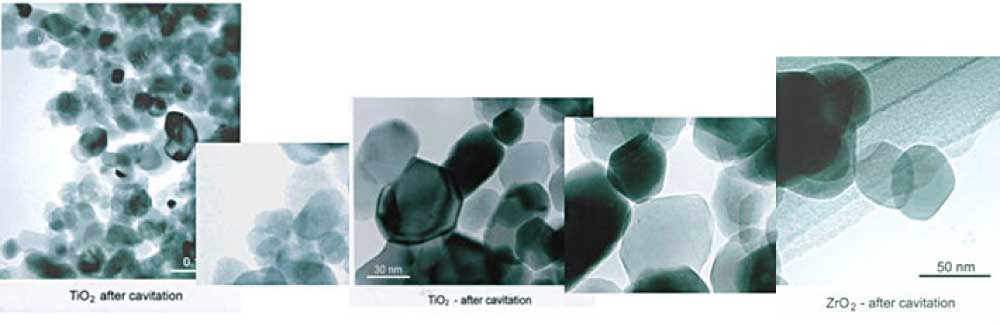

Cavities are effectively generated in the slurry, passing through the special designed disks and nozzle configuration, and then rapidly collapsed reaching at the open area.

The high energy is cleated over the particles, when the cavities are disappearing.

The Process, "Cavitataion Damage" enforces the crushing, dispersing, and emulsifying, which creates such fine nano particles.

APPLICATIONS

PIGMENT

CARBON BLACK

CMP SLURY

RARE METALS

NICKEL

ALUMINA

ZIRCONIUM

CARBON NANO TUBE

COSMETIC MATERIALS

CERAMICS

FERRITE MIX POWDER

ALUMINUM CHLORIDE

CARBON MATERIAL

DRUG MATERIAL

METAL POWDER

GRAPHITE

SILICA

FOOD ADDITIVES

& OTHERS

| MATERIALS | PROCESSING | SOLVENT | PROCESSING | REMARKS | ||

| D50 (μm) |

D90 (μm) |

D50 (μm) |

D90 (μm) |

|||

| ALUIMINA | 3.41 | 5.10 | WATER | 1.98 | 3.40 | 150MPa /1Pass |

|---|---|---|---|---|---|---|

| INDIUM | 0.34 | 2.12 | ETHANOL | 0.08 | 0.12 | 130MPa /3Pass |

| CARBON BLACK |

25.13 | WATER | 0.98 | 130MPa /2Pass |

||

| COBALT | 6.72 | 11.80 | 1.73 | 2.98 | 150MPa /3Pass |

|

| ZINC OXIDE |

3.60 | 6.70 | WATER | 0.45 | 1.32 | 100MPa /3Pass |

| TITANIUM OXIDE |

19.20 | 0.23 | 100MPa /3Pass |

|||

| MAGNETIC MATERIAL (MSG-W11) |

0.38 | 0.08 | 100MPa /5Pass |

|||

| ZIRCONIUM | 26.80 | WATER | 0.46 | 100MPa /3Pass |

||

| CALCIUM CARBONATE |

0.45 | 1.51 | WATER | 0.18 | 0.24 | 150MPa /3Pass |

| NICKEL | 0.88 | 4.47 | 0.41 | 0.52 | 150MPa /3Pass |

|

| γ-HEMUTITE | 2.00 | 0.43 | 100MPa /3Pass |

|||

| LITIUM ALUMINATE (LiAIO2) |

19.78 | 0.32 | 100MPa /3Pass |

|||

| MODEL | LSU-2010P14 | DSU-2515P16 | PR-***/*** |

| MAX PRESSURE (MPa) |

200 | 250 | 30~200 |

|---|---|---|---|

| MAX FLOW RATE (L/h) |

10 | 15 | 30~3,000 |

| CONSUMPTION OF ELECTRICITY (k/W) |

1.5 | 2.5 | 3.7~5.5 |

| DIMENSION (W×D×H/mm) |

600(W)× 550(D)× 400(H) |

700(W)× 700(D)× 1400(H) |

CUSTOMER REQUIREMENT BASIS |

| DRIVE | AC 200V | AC 200V | |

| REMARKS | FOR LABO & SMALL PRODUCTION |

CHILLED WATER NEEDED |